Mondragon Assembly is a leader in turnkey customized automation solutions for battery manufacturing. We offer scalable, efficient processes tailored to your needs.

Our solutions cover everything from cell unpacking and sorting to welding and complete battery and BMS testing

Custom and scalable automation

Which processes would you like to automate in your battery assembly line?

You decide what you want to automate, and we help you create the process, always thinking about today, but also about the future, so you can integrate as many new automations as you like.

Unboxing

Automatic or manual unpacking stations for cells.

Sorting

Classification of cells by internal resistance or voltage.

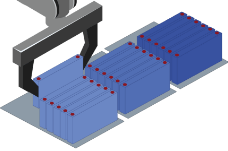

Stacking & Module Assembly

Stacking of cells into modules.

Welding

Resistance or laser welding.

Pack Assembly

Complete battery pack assembly, integrating the modules.

BMS / Cooling System Assembly

Automatic or manual assembly of the Battery Management System (BMS) and/or cooling system.

BMS Testing

Testing of the Battery Management System to ensure its proper functioning.

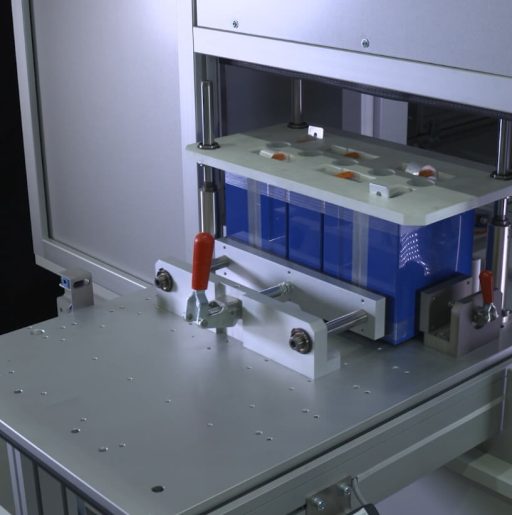

Cycling

We design customized cycling, simulating the actual battery expansion. Testing its charge and discharge repeatedly to verify its performance.

Advantages

What you get with a Mondragon Assembly solution

We support you in making your design more automatable

Custom-made assembly line

Possibility of increasing production capacity by adding modules

Support from our R&D team for CE pre-certification of batteries

R&D team dedicated to the project and collaboration with technology centers

Support for supplier selection and access to our network of collaborator

About Us

Solution provider more than a machine builder.

We have over 45 years of experience in automating processes. We have a global presence with 7 plants worldwide. We are part of one of the most important business groups in the world, the Mondragon Group.”

We invest 6% of our sales in R&D.

We have our own team dedicated to battery development.

Innovation is in our DNA.

We collaborate with technology centers such as Ikerlan and Tecnalia.

We are part of associations like BEPA and UPCELL.

FAQs

FAQs What do you get with a Mondragon Assembly solution?

Can the capacity of the assembly line be expanded?

Yes, our assembly lines are modular and scalable, which allows you to increase capacity according to your production needs.

Can different battery models be produced on the same line?

Yes, our lines are versatile and can be adapted to produce various battery models without the need for complex changes.

Is it necessary to have previous experience with batteries to start the design of the assembly line?

It is not essential to have a previous design. The R&D centers and our team advise you from the concept to the implementation of the line, including advice on the design of the battery, if necessary.

Is it possible to purchase individual stations?

Yes, specific stations can be purchased according to your requirements. Our solutions are tailored to your needs.

Is it necessary to have a battery design to start the assembly line?

It is not essential to have a prior design. Our development centers and team provide guidance from concept to line implementation, including battery design if needed.

Contact Contact Contact

Contact Contact Contact

Contact Contact Contact